In the ever-evolving landscape of automotive engineering, the pursuit of power, performance, and efficiency is a constant endeavor. Among the innovations that have reshaped the way we approach engine performance, forced induction turbochargers stand tall. In this blog post, we’ll embark on a journey to demystify forced induction turbochargers, exploring their mechanics, benefits, and their transformative impact on modern engines.

Forced induction turbochargers, often simply referred to as “turbochargers,” are devices designed to boost an engine’s power output by increasing the amount of air delivered to the combustion chamber. These devices are driven by the engine’s exhaust gases, harnessing the energy from these gases to compress the intake air and improve overall combustion efficiency.

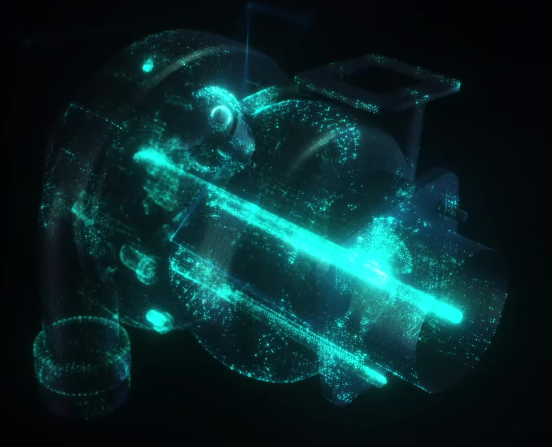

The key components of a turbocharger include the turbine housing, compressor housing, and CHRA. The engines exhaust gases flow through the turbine housing, causing the CHRA to spin at high speeds. As the CHRA turbine wheel spins, it drives the connected compressor wheel, which draws in and compresses the ambient air through its compressor housing before sending it into the engine’s intake manifold. The compressed air, combined with fuel, results in a more potent combustion process, leading to not only increased horsepower and torque but also fuel efficiency as the engine did not have to work as hard to receive the air it took in thanks to the turbochargers effectiveness.

Utilizing the forced induction method of turbocharging has forever transformed the landscape of automotive performance with 1 in 3 currently manufactured vehicles utilizing one today. With their ability to extract more power from engines without increasing displacement, these devices have played a pivotal role in achieving the delicate balance between power, efficiency, and environmental responsibility. Now through the application of advanced engineered apparatuses, like the Hlava Sequential-Turbo Manifold, anyone that has an internal combustion engine designed for forced induction can maximize the effectiveness and efficiency turbochargers were originally designed to provide, propelling their vehicle(s) to new levels of performance and exhilaration.

We’re always looking for new opportunities and are comfortable working internationally. Please get in touch and one of our project managers will contact you about beginning the proposal process.