The hindrance of compromise in turbocharger application is arguably more troubling in single turbocharger settings as a single frame size turbocharger will have a more limited range in the RPM band where it can effectively and efficiently generate and maintain a response. Achieving peak performance across a wide RPM range can be challenging with a single turbocharger, leading to compromises in power delivery at certain points. If you are searching for an early response, a smaller turbine housing will be required, but you will then not be able to optimize air delivery from the compressor housing which is where the horsepower is derived. For example, utilizing a g30-900 can supply the engine with enough air flow to achieve the 900hp it is rated for, but if you are utilizing the smallest turbine housing available for it, it is not likely without complex tuning and complex wastegate applications. Even then, you will likely need to push that turbocharger to inefficient/unreliable areas in its maps. Choosing a larger turbine housing will give you top end performance but there will be lag in response in the beginning of the RPM band. Your engine will have to work hard and on its own to get to a point where it is able to supply the turbocharger with sufficient exhaust gas to generate a response from the turbocharger. This results in the need for implementation of wastegates and electronic boost controllers to counter the lag. Using these may then end up forcing the turbochargers to work in very inefficient ways and supply your engine with a less-than-optimal boost quality. Because of these reasons, often, the compromised path chosen is a turbocharger that responds more in the middle of the RPM band. This way there is turbo response in the range of RPM that cars will spend most of their load bearing driven time in. Wastegates and boost control are still necessary, and there is still a lack of performance in both the beginning and end of the RPM band. Using the Hlava Sequential Turbo Manifold, engines (when paired accordingly) can experience the responsiveness of a small turbocharger along with a seamless transition of response to the larger secondary turbocharger coordinated with the maximum capabilities of the engine it is applied to for the high-end performance. In addition to the interlap of the two turbochargers in the middle of the RPM band, the apparatus allows you to eliminate the need for a compromise in turbocharger selection.

As previously stated, the use of a wastegate and electronic boost controller is necessary to assist the turbocharger to work where it otherwise will not and to protect the engine from excessive back pressure and detrimental situations such as boost spikes. With the use of more components, tuning becomes an increasingly challenging task as each component will need to be tuned to react with one-another properly. Using the Hlava Sequential Turbo Manifold with its designed intent being optimized performance with synchronized efficiency, there is no need for a wastegate as the larger turbocharger can accept all the exhaust gas in its housing. Also, without being set to achieve a target boost level, the turbochargers can function and create boosts at only efficient and effective points of their maps and never being overworked. With this, the primary tuning focuses become fuel and ignition adjustments, eliminating boost control. Saving you quite a bit on tuning costs where most implement multiple tuning files for different intentions (daily driving/fuel economy, performance, etc…), and the price of all the components that would otherwise be necessary.

When turbochargers are set to hit a target boost level, the way the vast majority of setups with wastegates and boost controllers do, the ecu is programmed to force the turbocharger/s to create that target boost level by the means programmed in the ecu, which can include making the turbochargers work outside of their efficiency zones and rotate at levels greater than they can reliably operate at. In doing so, the intake temperatures elevate which robs the air of usable energy, making that boost inefficient. Because the designed intent of the Hlava Sequential Turbo manifold does not involve overworking the turbochargers at any given time, it then promotes cooler intake temperatures, allowing the air to sustain a higher threshold of usable energy, making each pound of boost more valuable comparative to hotter boost pressure. In other words, you can achieve more power per psi at lower temperatures than you would see at higher intake temperatures that are relative to other turbocharger applications.

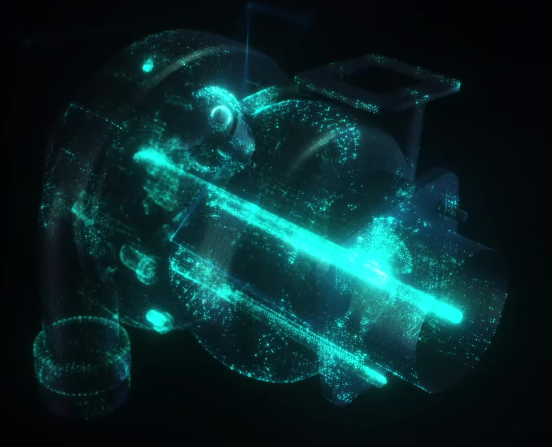

In the ever-evolving landscape of forced induction, the Hlava Sequential-Turbo Manifold emerges as a game-changing solution that marries immediate response, consistent performance, and efficiency, all without the complexities inherent in single turbocharging. As the automotive industry moves forward, the HST manifold paves the way towards a more accessible, adaptable, and high-performance forced induction experience.

We’re always looking for new opportunities and are comfortable working internationally. Please get in touch and one of our project managers will contact you about beginning the proposal process.