In the realm of automotive performance, the quest for power and efficiency has led to remarkable innovations. Among these, sequential turbochargers have emerged as a game-changing technology, redefining the boundaries of engine performance. In this blog post, we’ll dive into the world of sequential turbochargers, exploring their mechanics, advantages, and their role in shaping the future of high-performance engines.

Sequential turbocharging is a sophisticated method of forced induction that combines the benefits of different-sized turbochargers to optimize engine performance across a wide range of RPMs. This innovative approach addresses the inherent limitations of traditional single-turbo setups, which often require a compromise between low-end responsiveness and high-end power.

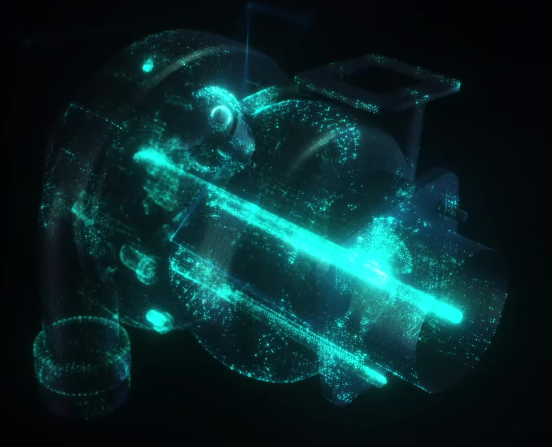

At the core of sequential turbocharging lies a dual-turbo system, where two turbochargers are strategically integrated into the engine’s intake and exhaust systems. These turbochargers are often referred to as the “primary” and “secondary” turbos.

The sequential turbocharging process involves an orchestrated sequence of operations:

Sequential turbochargers represent a pinnacle of engineering ingenuity, combining the benefits of quick response and high-end power delivery. This technology has transformed the way we perceive engine performance, offering a harmonious blend of power, efficiency, and driving exhilaration. As automotive engineering continues to advance, sequential turbochargers stand as a testament to human innovation, driving us closer to the threshold of unparalleled precision performance on the road and the track.

We’re always looking for new opportunities and are comfortable working internationally. Please get in touch and one of our project managers will contact you about beginning the proposal process.